In the realm of warehouse management, optimizing bin locations is a critical aspect that directly impacts operational efficiency, order fulfillment speed, and overall customer satisfaction. An organized system of zones, aisles, rows, bays, and bins ensures smooth inventory management, accurate order picking, and seamless replenishment processes. This article explores the importance of managing bin locations and provides insights into effective strategies for organizing and maintaining a well-structured warehouse.

Understanding the Hierarchy

To establish an efficient bin location system, it is crucial to comprehend the hierarchical structure of a warehouse. Let’s break it down:

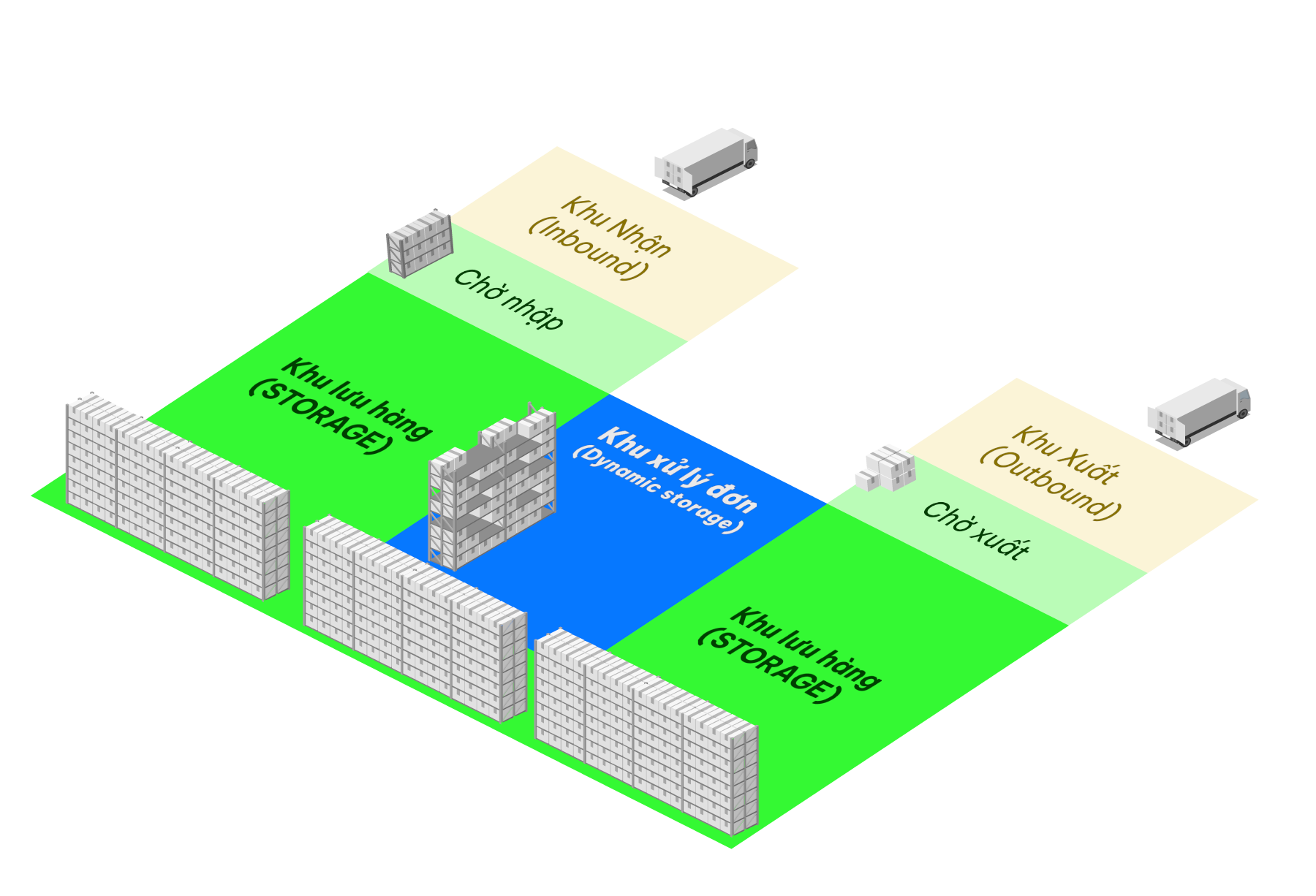

Zones

Dividing the warehouse into distinct zones based on product categories, characteristics, or storage requirements helps in streamlining inventory management. This allows for easier navigation and minimizes the time spent searching for items.

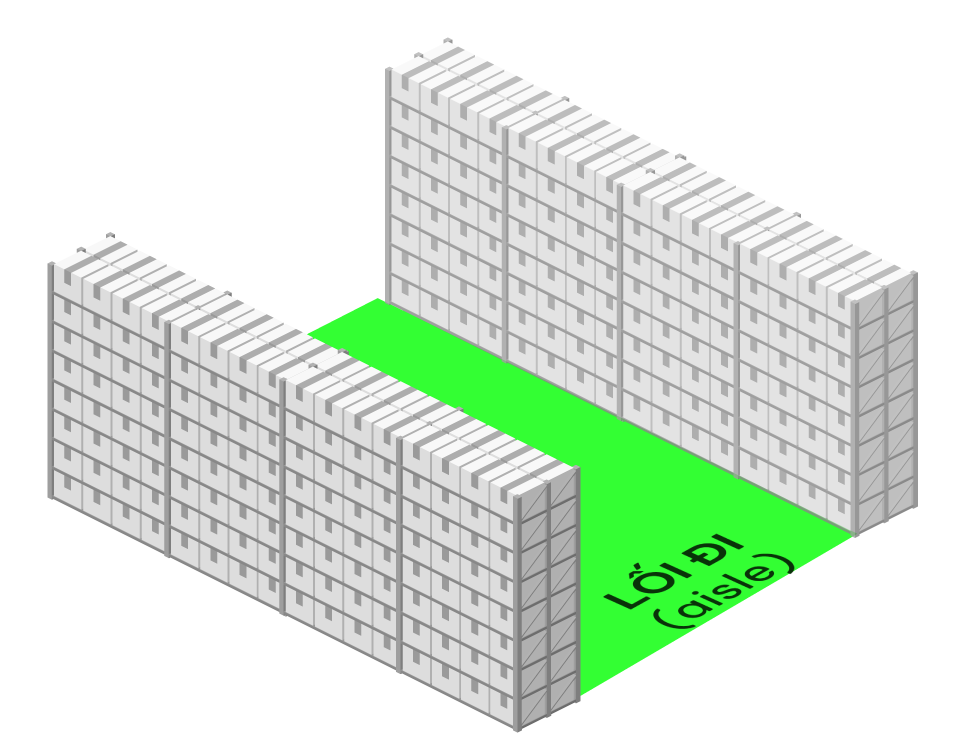

Aisles

Zones are further divided into aisles, which serve as pathways for the movement of personnel, equipment, and inventory. Proper aisle width is crucial to facilitate safe and efficient movement.

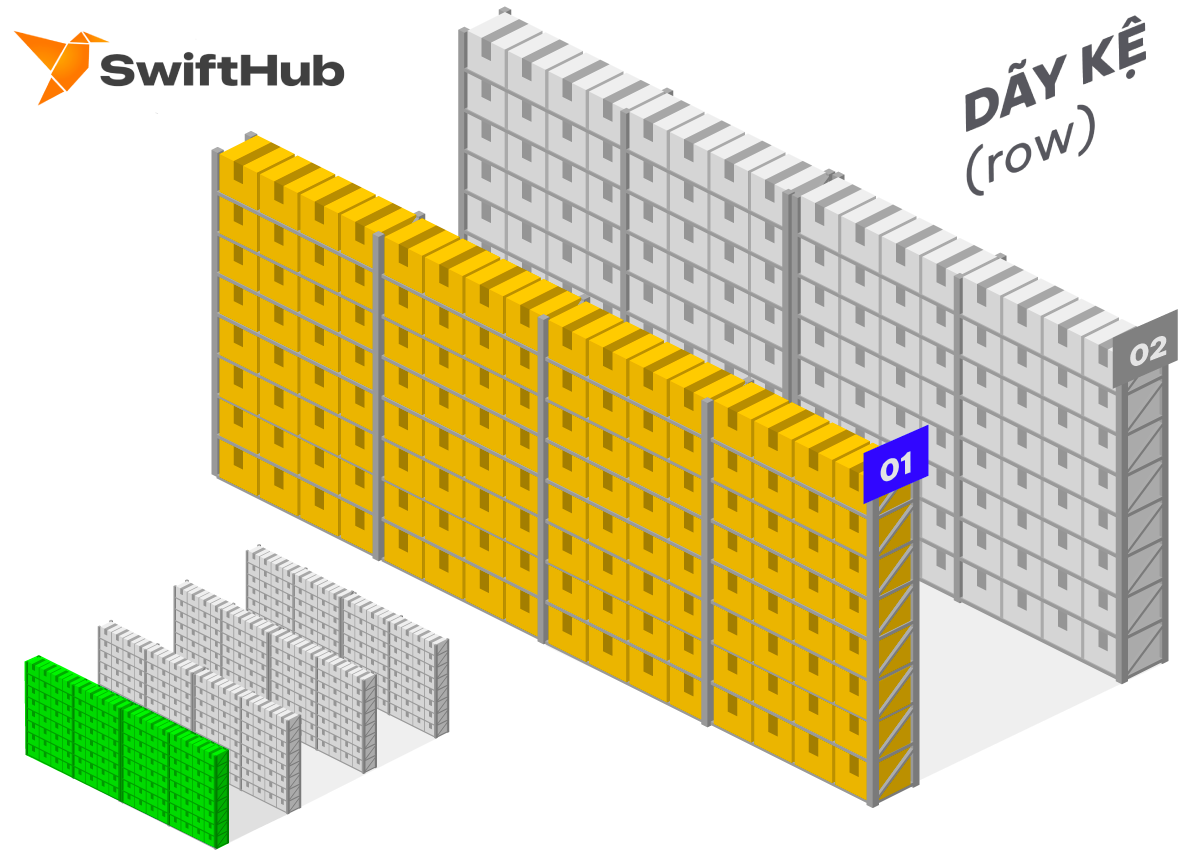

Rows

Aisles are lined with rows of racking or shelving systems. Rows are typically numbered or labeled to provide clear identification and facilitate easy navigation.

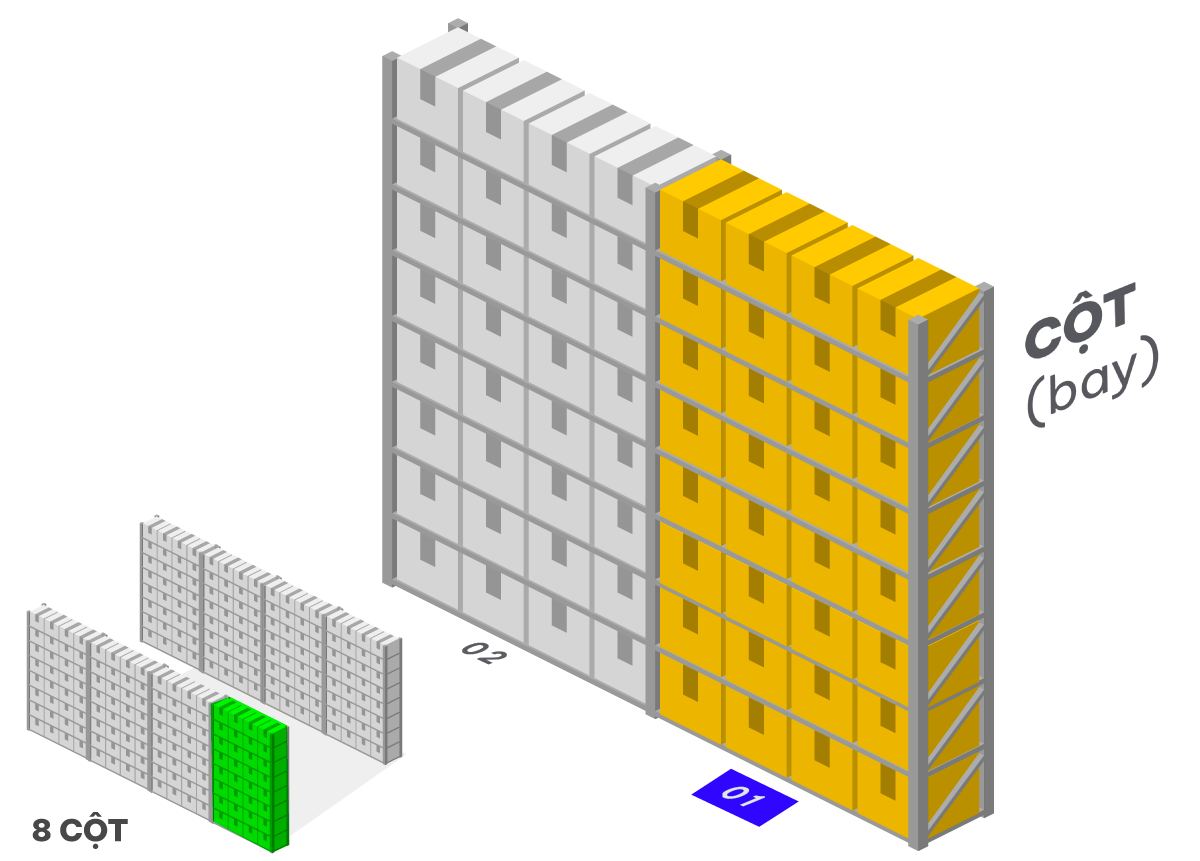

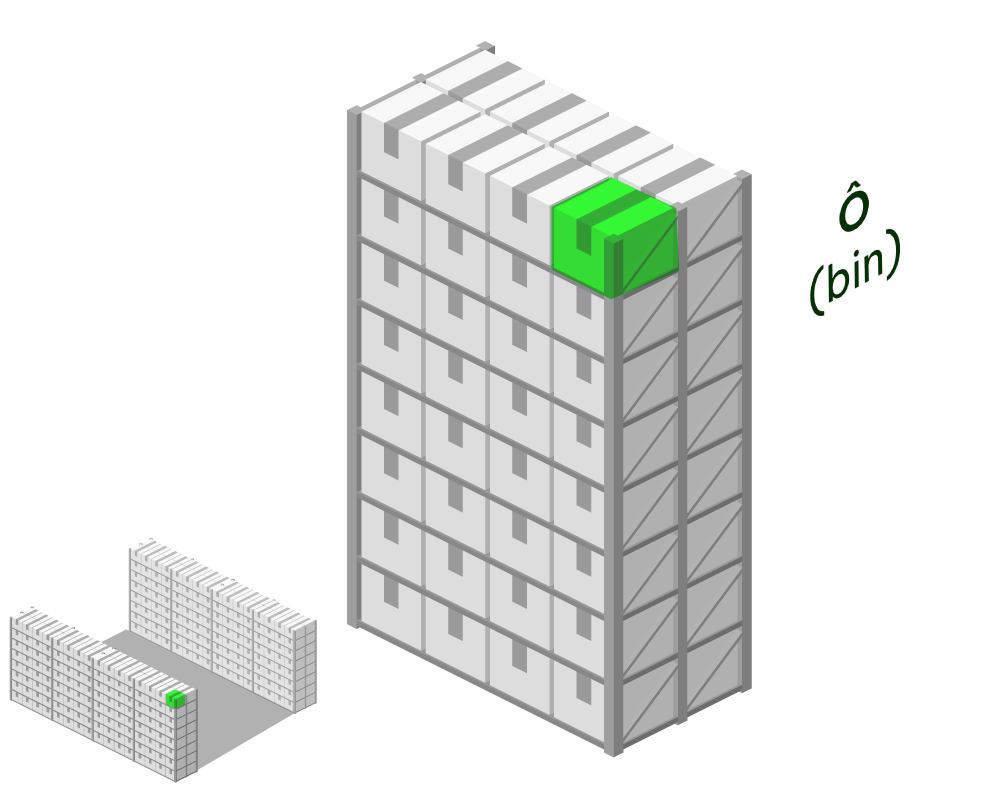

Bays

Rows are then divided into bays, which are sections of shelving or racking. Each bay can accommodate multiple bins.

Bins

Bins are the smallest units within the hierarchy and represent the specific storage locations within each bay. They are assigned unique identifiers, such as numbers or alphanumeric codes, to ensure accurate item retrieval.

Designing an Effective Bin Location System

Developing an efficient bin location system involves careful planning and consideration of various factors. Here are some key steps to follow:

Analyze Inventory Characteristics: Understand the nature of your inventory, such as size, weight, fragility, and storage requirements. Categorize items based on their characteristics and assign appropriate bin locations accordingly. For example, fragile items might require specific bin locations with extra protection or special handling instructions.

Optimize Flow: Organize your bin locations based on the flow of goods within the warehouse. Frequently picked items should be placed in easily accessible bins near packing and shipping areas, while slower-moving inventory can be stored in less accessible locations.

Utilize Technology: Leverage technology to enhance bin location management. Warehouse management systems (WMS) and inventory management software can help track inventory levels, automate stock rotation, and provide real-time visibility into bin locations.

Labeling and Signage: Clear labeling and signage play a vital role in efficient warehouse operations. Ensure that each zone, aisle, row, bay, and bin is prominently labeled with easily readable and scannable identifiers. This facilitates accurate and quick item retrieval, reduces errors, and enables new employees to navigate the warehouse effectively.

Implementing Best Practices

To maintain an organized bin location system, consider the following best practices:

Regular Audits: Conduct routine audits to ensure bin locations are accurately labeled, items are stored correctly, and inventory is properly tracked. This practice helps identify and rectify any discrepancies or inconsistencies.

Training and Documentation: Provide comprehensive training to warehouse staff on the bin location system, including proper handling and storage procedures. Maintain updated documentation that outlines the system’s structure, rules, and guidelines.

Continuous Improvement: Regularly evaluate the efficiency of the bin location system and make adjustments as needed. Monitor order fulfillment speed, inventory accuracy, and employee feedback to identify areas for improvement.

Seasonal Adjustments: Consider adjusting bin locations during peak seasons or for specific events to accommodate changes

Tiếng Việt

Tiếng Việt